Drum Cleaning Systems

High-Performance Drum & Barrel Cleaning Systems

Automated Solutions for Chemical, Food, and Industrial Applications

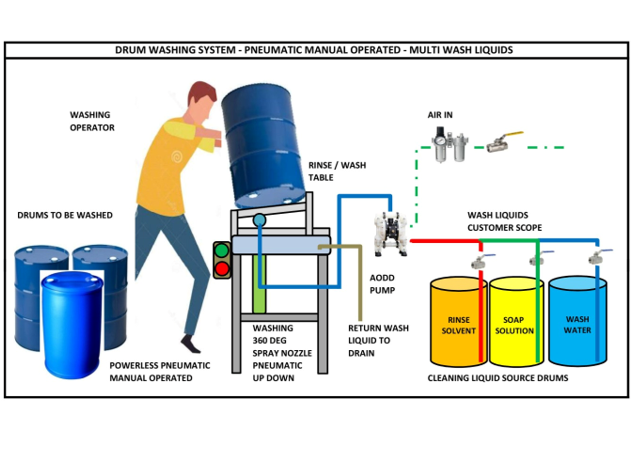

In industries where cross-contamination is a risk and manual cleaning is a bottleneck, our Dual-Pump Drum Cleaning System offers a turnkey solution. By combining the rugged versatility of Air-Operated Double Diaphragm (AODD) pumps with the precision of High-Pressure Plunger pumps, we deliver a system that cleans faster, uses less solvent/water, and ensures 100% residue removal.

How the System Works: The Power of Two

A superior cleaning cycle requires two distinct phases: high-impact impingement to remove scales and high-volume evacuation to prevent pooling.

The High-Pressure Scouring Phase

Powered by: High-Pressure Plunger Pumps

The heart of the cleaning power lies in the plunger pump. This unit generates the intense pressure required to feed specialized 360° rotating spray heads.

- Impact: Mechanical force strips away hardened resins, paints, food products, and chemical residues.

- Efficiency: High pressure allows for lower water/solvent consumption compared to standard wash-down methods.

- Durability: Designed for continuous duty with ceramic plungers and stainless steel manifolds.

The Rapid Evacuation Phase (Slop Removal)

Powered by: AODD (Air-Operated Double Diaphragm) Pumps

As the high-pressure head cleans the drum, the AODD pump acts as the “scavenger.”

- Solids Handling: AODD pumps easily handle the thick “slurry” of dislodged solids and cleaning fluids.

- Self-Priming & Run-Dry: These pumps can run dry without damage, ensuring every last drop of waste is suctioned out of the drum.

ATEX Certified: Safe for use with flammable solvents or in hazardous environments

Applications & Industries

Our systems are engineered to meet the stringent standards of:

- Chemical Manufacturing: Total removal of resins, inks, and adhesives.

- Food & Beverage: Sanitary-grade pumps for 3-A or FDA-compliant cleaning.

- Pharmaceutical: Validation-ready cleaning cycles to prevent cross-contamination.

Waste Management: Efficient reconditioning of industrial IBCs and 55-gallon drums.

Engineering Excellence You Can Trust

We don’t just sell pumps; we provide fluid dynamics expertise. Whether you need a stationary multi-drum station or a mobile cleaning cart, our systems are built with:

- Chemical-resistant seals (Viton, PTFE, or EPDM).

- Variable Frequency Drives (VFD) for precise pressure control.

- Stainless Steel frames for corrosive environments.

Key Benefits of the Integrated System

Feature | Advantage | Business Value |

360° Rotating Heads | No “blind spots” inside the drum. | Guaranteed Quality Control. |

Closed-Loop Option | Ability to filter and reuse cleaning agents. | Massive reduction in fluid costs. |

Automated Cycle | Removes operators from contact with chemicals. | Enhanced Workplace Safety. |

High Pressure (Up to 5000 PSI) | Cleans even the toughest “baked-on” materials. | Faster turnaround times. |

Custom Cleaning Systems

We provide custom-engineered drum cleaning systems tailored to drum type, residue characteristics, capacity requirements, and plant layout—ensuring efficient, safe, and reliable cleaning operations.