Barrel Pumps

Industries We Serve

- Chemical and Petrochemical Industries

- Food & Beverage Processing

- Oil & Gas

- Fuel and Gas Stations

Applications

- Lubricants & Oils

- Fuel Handling

- Non-Corrosive Solvents

- Coolants & Antifreeze

- Agriculture

- Hazardous and flammable fluid transfer

Barrel pumps

Barrel pumps are designed for safe, efficient transfer of liquids from drums, barrels, and intermediate containers. They are ideal for handling chemicals, acids, solvents, oils, and other industrial fluids. Our barrel pumps are available in Electric, Pneumatic, and Hand Operated versions, with multiple MOC options to suit a wide range of applications.

Why Choose Our Barrel Pumps?

- Wide range of Electric, Pneumatic, and Manual options

- Multiple MOC choices to suit all fluids

- Safe, efficient, and reliable liquid transfer

- Suitable for corrosive, flammable, and hygienic applications

- Custom solutions available as per customer requirements

Key Features

- Easy plug-and-play operation

- High flow rate with stable performance

- Suitable for continuous and intermittent duty

- Low maintenance and long service life

- Available with single-phase and three-phase motors

Pumps We Manufacture

Electric Barrel Pumps

Electric barrel pumps offer high efficiency, consistent flow, and ease of operation for continuous liquid transfer. They are widely used in chemical, pharmaceutical, food, and manufacturing industries where speed and reliability are critical.

Key Features

- Easy plug-and-play operation

- High flow rate with stable performance

- Suitable for continuous and intermittent duty

- Low maintenance and long service life

- Available with single-phase and three-phase motors

Material of Construction (MOC)

- PP (Polypropylene) – Suitable for mild chemicals and acids

- PVDF – Ideal for aggressive and corrosive chemicals

- Aluminium – Best for oils, fuels, and non-corrosive liquids

- SS304 – Suitable for food, pharma, and general chemicals

- SS316 – Ideal for highly corrosive fluids and hygienic applications

Typical Applications

- Chemical transfer from drums

- Acid and alkali handling

- Oil and lubricant transfer

- Pharmaceutical and food processing

Pneumatic Barrel Pumps

Pneumatic barrel pumps are air-operated and designed for hazardous and explosive environments. With no electrical components, they provide maximum safety while handling flammable, volatile, and aggressive liquids.

Key Features

- Spark-free and explosion-proof operation

- Suitable for hazardous areas (ATEX-friendly design)

- Can run dry without damage

- Easy flow control using air pressure

- Robust and reliable construction

Material of Construction (MOC)

- PP – Chemical and acid transfer

- PVDF – Strong resistance to highly corrosive fluids

- Aluminium – Solvents, fuels, and oils

- SS304 / SS316 – Hygienic and corrosive applications

Typical Applications

- Flammable liquids and solvents

- Chemical and petrochemical industries

- Paints, inks, and coatings

- Pharmaceutical and specialty chemicals

- Refineries and process plants

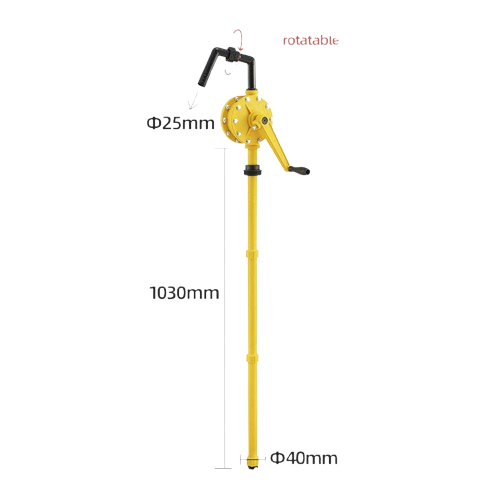

Hand Operated Barrel Pumps

Hand operated barrel pumps are economical and easy-to-use solutions for low-volume liquid transfer. They are ideal for locations where power or compressed air is not available.

Key Features

- Simple and portable design

- No electricity or air required

- Cost-effective and low maintenance

- Easy installation on standard barrels

- Reliable for intermittent usage

Material of Construction (MOC)

- PP – Acids, chemicals, and water-based liquids

- Aluminium – Oils, diesel, and fuels

- SS304 / SS316 – Food-grade and chemical applications

Typical Applications

- Small-scale chemical handling

- Oil and fuel dispensing

- Maintenance workshops

- Laboratories and utility areas

Ready to Optimize Your Flow?

Get in touch with Yash Flow today for a consultation or a competitive quote.