Automation Solutions Systems

for Industrial Pumps & Piping Systems

Smart Automation for Reliable Fluid Handling

Automation in industrial pump and piping systems enhances efficiency, safety, accuracy, and operational reliability. By integrating advanced control systems, sensors, and smart monitoring, automated pump and pipe networks ensure consistent performance with minimal manual intervention across industries such as chemical processing, pharmaceuticals, water treatment, food & beverage, oil & gas, and manufacturing.

Key Automation Processes in Pumps & Piping

Automated Pump Control

-

Intelligent start/stop sequencing

-

Variable Frequency Drive (VFD) speed control

-

Pressure-based and flow-based automation

Automated control optimizes pump operation, reduces energy consumption, and extends equipment life.

Flow & Pressure Monitoring

-

Flow meters for real-time measurement

-

Pressure transmitters for system stability

-

Automatic flow balancing and regulation

These systems maintain precise flow rates and pressure levels, preventing system failures and downtime.

Valve Automation

-

Pneumatic and electric actuated valves

-

Automated flow diversion and isolation

-

Emergency shut-off systems

Valve automation improves response time, enhances safety, and allows seamless process control.

Integrated Sensor Technology

- Level sensors for tanks and pipelines

- Temperature sensors for process safety

- Leak detection and alarm systems

Sensors provide continuous data for proactive maintenance and fault prevention.

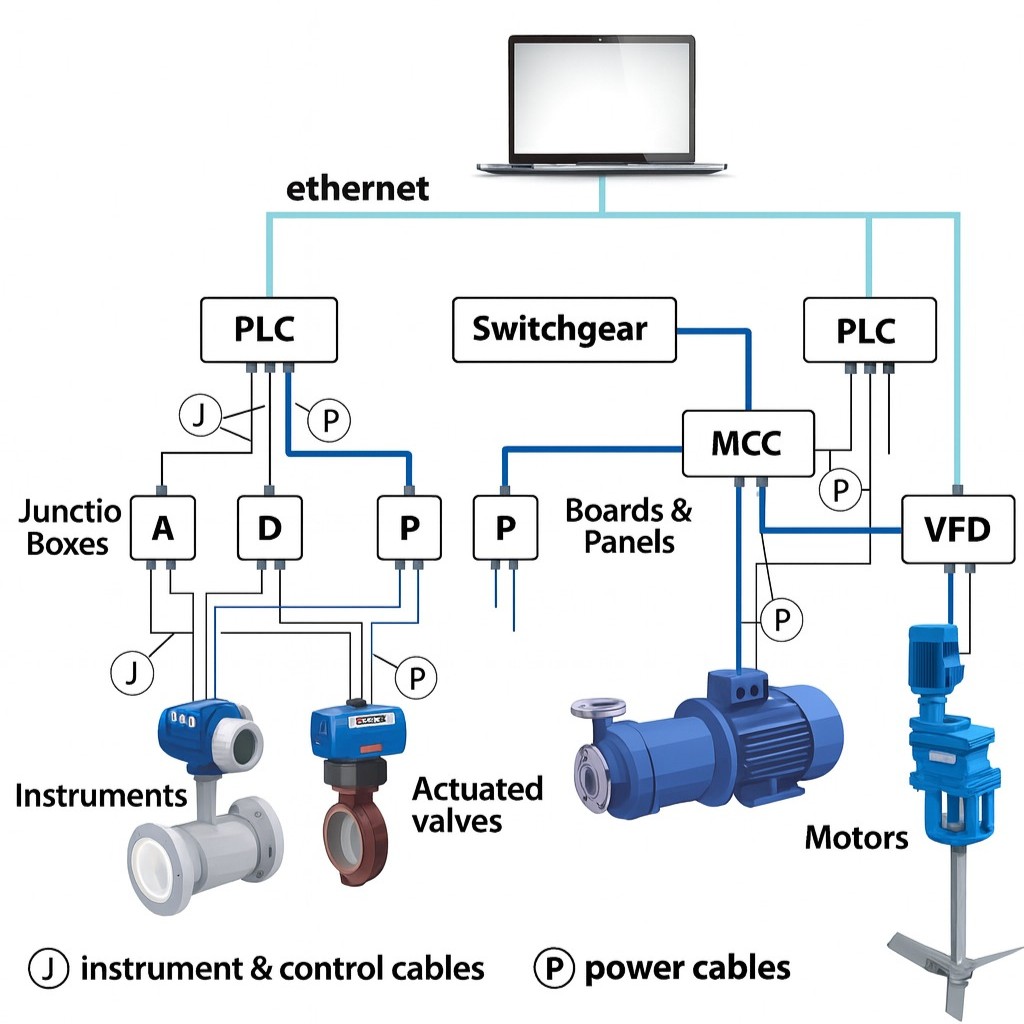

PLC & SCADA Integration

-

Programmable Logic Controller (PLC) based automation

-

SCADA systems for centralized monitoring

-

Remote operation and data logging

These systems allow operators to control, analyze, and optimize processes from a single interface.

About Our Automation Systems

An automation system is a combination of control hardware, sensors, actuators, and software that enables automatic operation of industrial processes with minimal human intervention. These systems are typically powered by PLC, SCADA, and smart control panels, allowing real-time monitoring, data logging, and remote operation. Automation systems are compact, reliable, and designed to deliver accurate control of flow, pressure, level, and dosing parameters across water, chemical, steam, and gas applications.

Benefits of Automation Systems

- Improved operational efficiency

- Reduced manual errors and labor costs

- Energy optimization and cost savings

- Enhanced process safety

- Predictive maintenance and reduced downtime

- Consistent product quality

Industries We Serve

Chemical & Process Industries

Water & Wastewater Treatment

Pharmaceuticals & Biotechnology

Food & Beverage Processing

Power Plants

Oil, Gas & Petrochemicals

Future-Ready Pump & Pipeline Automation

Automation transforms conventional pump and piping systems into smart, data-driven infrastructure. With scalable automation solutions, industries can achieve higher productivity, improved safety, and long-term operational excellence.