Dosing Systems

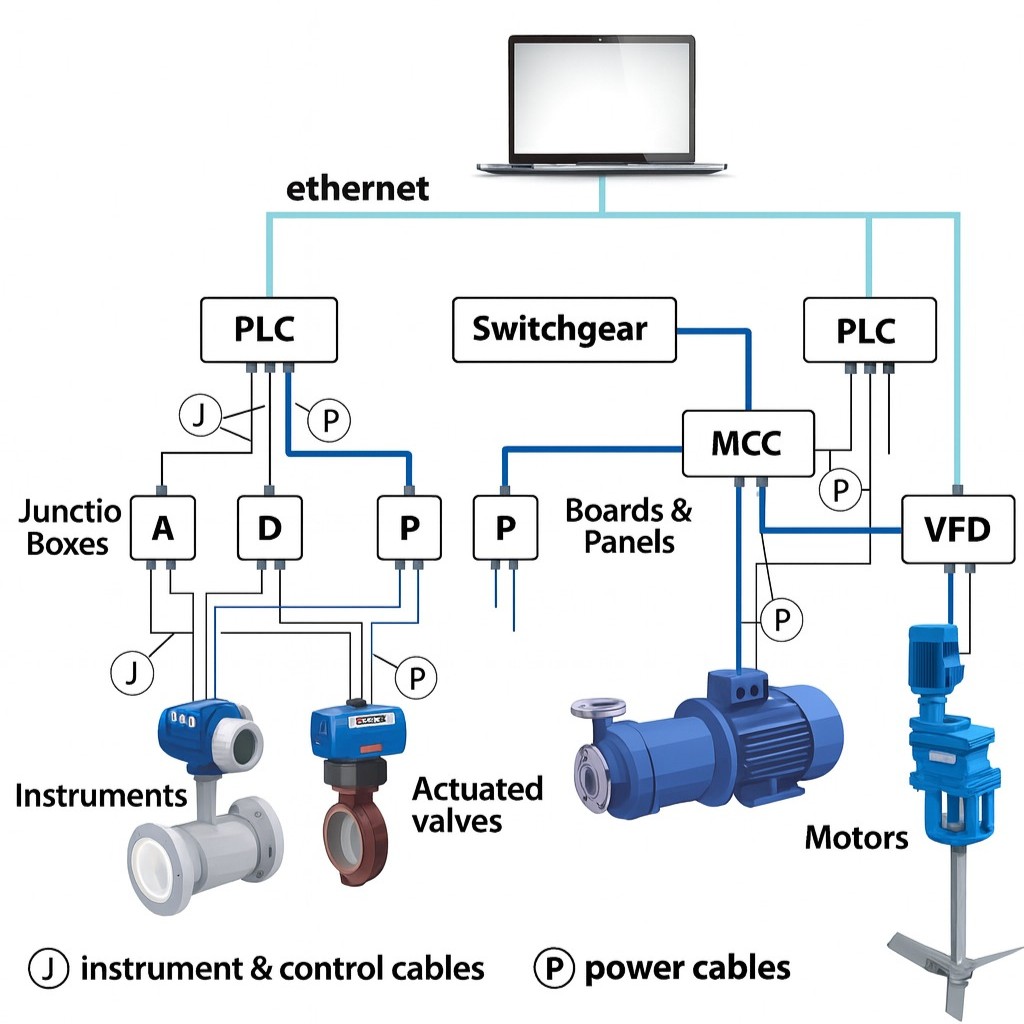

Automation Systems

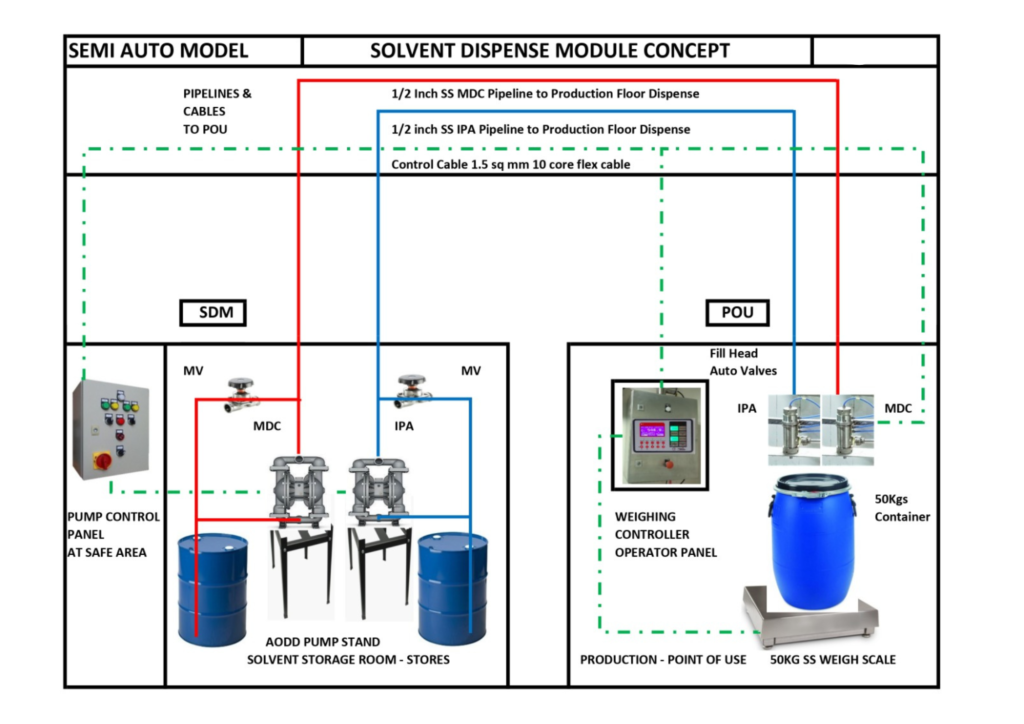

Solvent Dispensing Systems

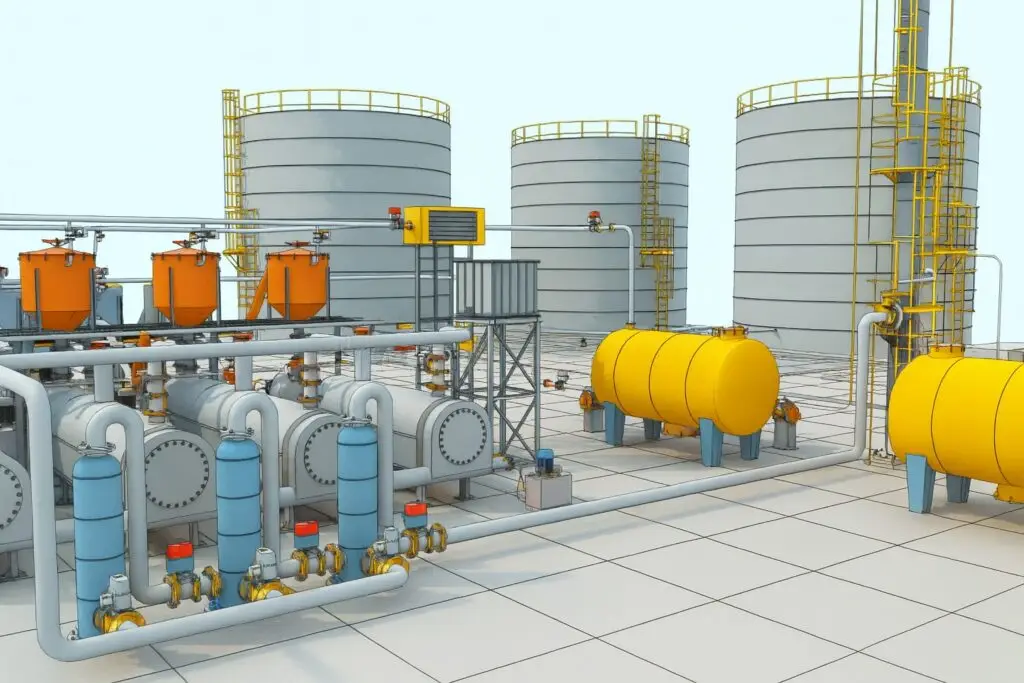

Storage Systems

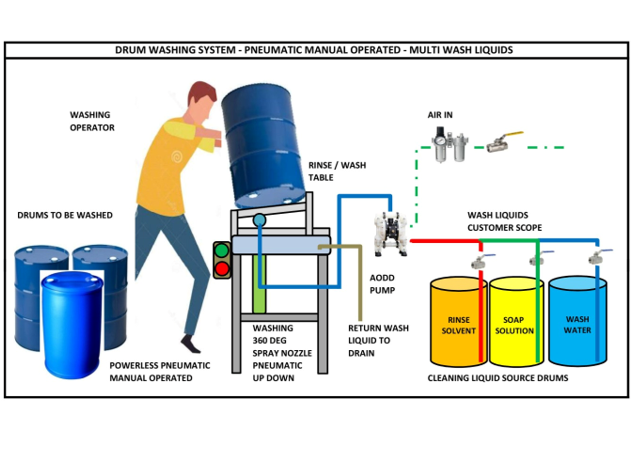

Drum Cleaning Systems

Integrated Process Systems by Yash Flow Technologies

At Yash Flow Technologies, we specialize in the design and fabrication of complete, skid-mounted and modular process systems. Our solutions—ranging from chemical dosing and automation systems to Drum Cleaning, Solvent Dispensing, Drum Cleaning and storage systems—are engineered to deliver a safe, efficient, and automated approach to fluid handling and process control.

Each system is custom-built to meet your exact operational requirements, ensuring accuracy, consistency, and long-term reliability across diverse industrial applications.

System Components & Workflow

Every Yash Flow system is a fully synchronized assembly designed for plug-and-play installation and seamless integration into existing plants:

Storage & Preparation Units

Custom-designed HDPE, PP, MS, or SS316 tanks and vessels equipped with level indicators, vents, and safety fittings.

Pumping & Transfer Systems

High-precision dosing, transfer, or circulation pumps—available in single or duplex configurations—for accurate and reliable fluid movement.

Agitation, Mixing & Cleaning Modules

Integrated agitators, mixers, spray nozzles, or cleaning assemblies to ensure uniform concentration, effective residue removal, or controlled dispensing.

Piping, Valves & Safety Accessories

Chemical- and solvent-resistant piping, isolation valves, strainers, pressure relief devices, and containment systems designed for safe operation.

Automation & Control Command Center

Centralized electrical control panels with optional PLC/HMI, sensors, and interlocks for automated sequencing, monitoring, and flow regulation.

Why Choose Our Process Systems?

Precision & Process Control

Engineered to deliver accurate flow rates, controlled dispensing, and repeatable results—minimizing wastage and improving efficiency.

Compact & Space-Efficient Design

Skid-mounted and modular layouts allow easy installation within limited plant spaces or retrofit environments.

Built for Demanding Applications

All components are selected to withstand corrosive chemicals, solvents, high pressures, and continuous-duty operations.

Single-Source Engineering & Manufacturing

With in-house expertise in pumps, agitators, motors, and system integration, we ensure every component works in perfect harmony for optimum performance.

Scalable & Customizable

Systems can be expanded, automated, or modified to meet future process changes or increased capacity demands.