Dosing Pumps

Industries We Serve

- Water Treatment

- Chemical Process

- Food & Beverage

- Power Generation

- Textile & Paper

Applications

- Dosing of chlorine, pH adjusters, and coagulants.

- Injection of corrosion inhibitors and biocides

- Precise injection of catalysts and additives.

- Accurate dosing of flavors, colors, and preservatives

Dosing Pumps

Precision Fluid Management & Dosing Solutions

At Yash Flow, we define excellence in fluid engineering. We specialize in the manufacturing and supply of high-performance dosing pumps designed for accuracy, durability, and efficiency. Whether you are in water treatment, chemical processing, or industrial manufacturing, our pumps ensure that your critical fluids are handled with the utmost precision.

How an Dosing Pump Works?

Dosing pumps use a precise reciprocating mechanism to displace a specific volume of liquid with every stroke. A motor or solenoid drives a diaphragm or plunger, creating alternating suction and discharge cycles through non-return check valves. This positive displacement design ensures extremely accurate flow control, making them essential for chemical injection and critical fluid management.

Why Choose Yash Flow?

We offer high-precision Dosing Pumps designed for exact chemical injection, maximum durability, and consistent, accurate performance. Our pumps are expertly engineered to minimize chemical waste, handle aggressive fluids safely, and deliver repeatable flow rates for your critical industrial processes.

- Accuracy: We guarantee dosing accuracy across our range.

- Customization: We tailor pump heads, seals, and motors to fit your specific chemical compatibility needs.

- After-Sales Support: Our dedicated team ensures spare parts availability and technical guidance.

- Quality Assurance: Every pump undergoes rigorous testing for pressure and flow before leaving our facility.

Our Product Range

We offer a versatile range of dosing pumps engineered to meet distinct pressure and flow requirements.

Electronic Dosing Pumps

Precision Control for Critical Additives.

Ideal for applications requiring high accuracy and low-flow chemical injection. Our Electronic Dosing Pumps are solenoid-driven and offer digital precision for complex dosing tasks.

- Key Features:

- Digital Interface: Easy-to-read LCD display for stroke frequency and flow rate adjustments.

- Chemical Resistance: Heads available in PP, PVDF, and SS316 to handle aggressive chemicals.

- Automation Ready: Compatible with 4-20mA inputs and pulse signal control.

- Best For: Water treatment (RO plants), pH correction, and lab-scale chemical dosing.

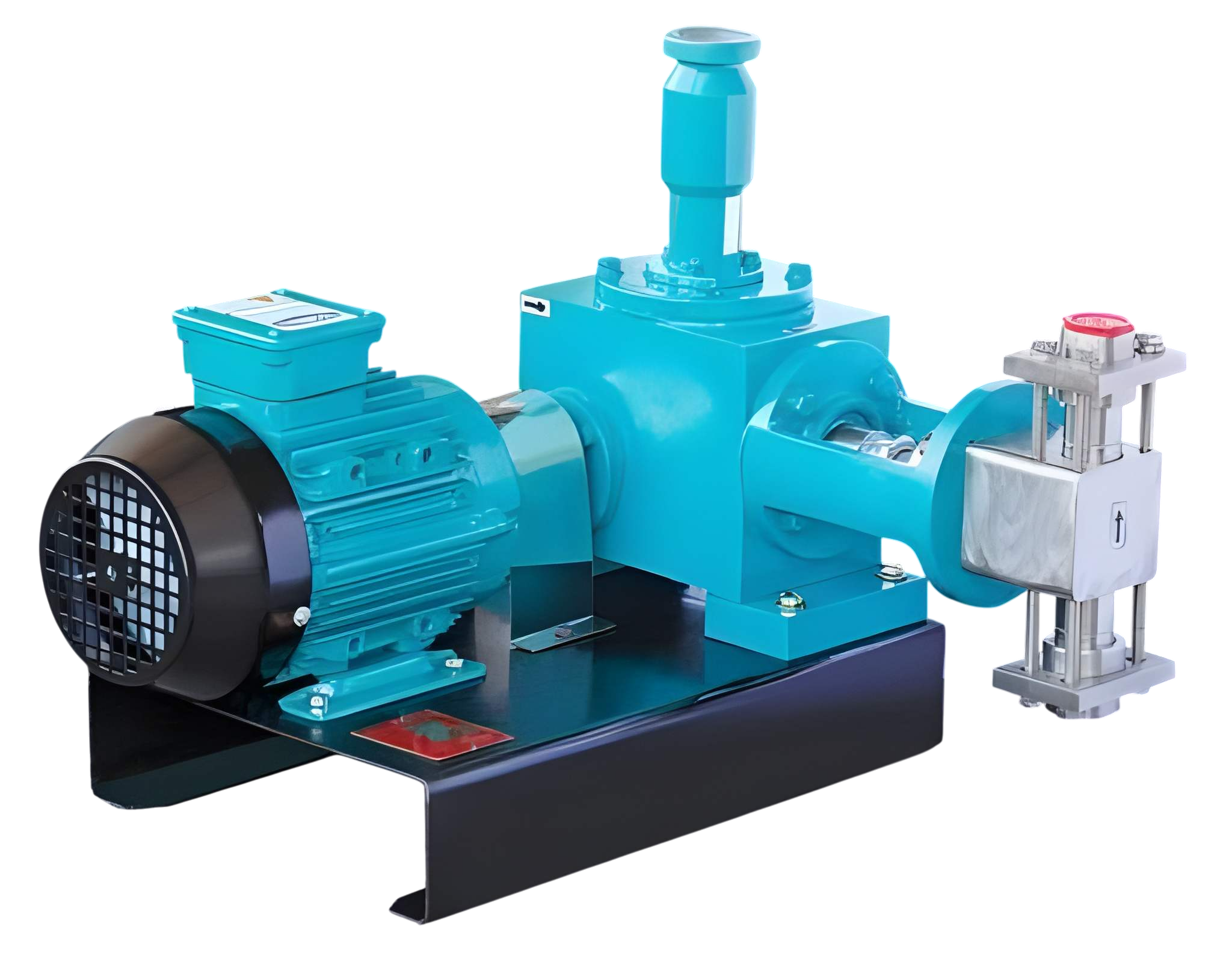

Mechanical Dosing Pumps (Diaphragm Type)

Rugged, Reliable, and Cost-Effective.

The workhorse of the industry. The Yash Flow Mechanical Diaphragm Pump uses a direct motor drive to mechanically actuate the diaphragm, ensuring a safe, leak-free operation at a lower cost of ownership.

- Key Features:

- Zero Leakage: Hermetically sealed diaphragm design prevents chemical leaks.

- Low Maintenance: Simple gearbox mechanism with fewer moving parts.

- Adjustable Flow: Micrometric stroke adjustment knob for varying flow rates (0-100%) while in operation.

- Best For: Wastewater treatment, cooling towers, and general chemical transfer.

Plunger Type Dosing Pumps

High Pressure, High Efficiency.

When you need to move viscous fluids or operate at high discharge pressures, Yash Flow Plunger Pumps deliver. These pumps utilize a reciprocating plunger to displace fluid directly, offering high volumetric efficiency.

- Key Features:

- High Pressure Capability: Capable of operating at pressures up to 400 kg/cm².

- Heavy Duty Construction: Pistons made from ceramic or hardened stainless steel for longevity.

- Viscosity Handling: Excellent for dosing viscous liquids, oils, and slurries.

- Best For: Boiler feed applications, oil & gas industry, and high-pressure reactors.

Hydraulic Dosing Pumps

The Ultimate in Safety and Durability.

Designed for the most demanding environments, our Hydraulic Dosing Pumps combine the high-pressure capability of a plunger pump with the leak-proof safety of a diaphragm pump. The diaphragm is actuated by hydraulic oil, ensuring it remains balanced and stress-free.

- Key Features:

- Built-in Safety: Integrated pressure relief valve to protect the pump from over-pressure.

- Long Diaphragm Life: Hydraulically balanced diaphragm minimizes wear and tear.

- Rupture Detection: Optional alarm systems to detect diaphragm failure immediately.

Best For: Toxic, radioactive, or flammable liquids, and continuous duty processes in petrochemical plants.

Ready to Optimize Your Flow?

Get in touch with Yash Flow today for a consultation or a competitive quote.