Screw Pumps

Applications

- Moving thickened sludge

- Polymer dosing

- Handling crude oil

- Chemical Transferring abrasive slurries

- Moving mineral slurries

Industries We Serve

- Wastewater

- Food & Beverage

- Oil & Gas

- Chemical

- Mining

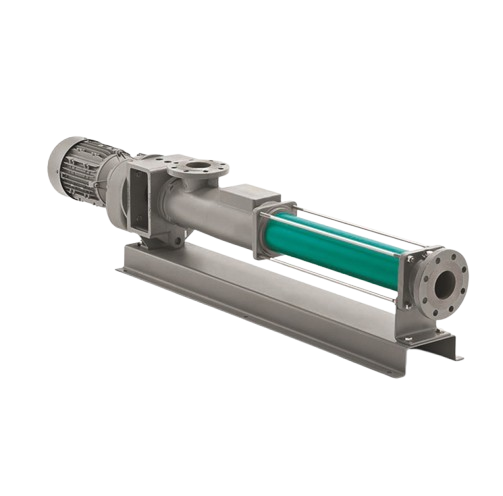

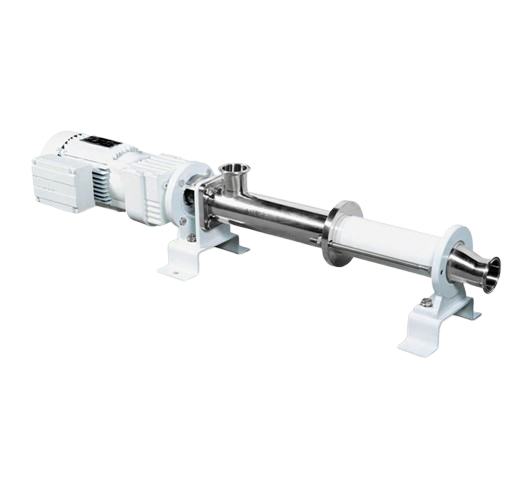

Progressive Cavity Pumps: The Solution for Challenging Fluids

Progressive cavity (PC) pumps—often called screw pumps or helical rotor pumps—are a type of positive displacement pump designed to handle the “tough stuff.” Unlike centrifugal pumps that rely on speed, PC pumps use a precision-engineered internal geometry to move fluids steadily and gently.

How It Works: The Rotor and Stator

The core of a progressive cavity pump consists of two main components:

- The Rotor: A single-helix metallic screw.

- The Stator: A double-helix sleeve, usually made of a flexible elastomer.

As the rotor turns inside the stator, it creates a series of sealed cavities that move from the suction end to the discharge end. Because these cavities are fixed in volume, the pump delivers a pulsation-free, consistent flow regardless of changes in pressure.

Common Applications

Progressive cavity pumps are the workhorses of several major industries:

Industry | Common Usage |

Wastewater | Moving thickened sludge, dewatered sludge cake, and polymer dosing. |

Food & Beverage | Transporting sauces, chocolate, dairy products, and fruit pulps. |

Oil & Gas | Handling crude oil, multiphase fluids, and produced water. |

Chemical | Transferring abrasive slurries, adhesives, and paints. |

Mining | Moving mineral slurries and explosive emulsions. |

Maintenance & Longevity

To ensure your PC pump operates efficiently, it is vital to monitor two factors:

- Dry Running: These pumps rely on the fluid for lubrication; running them dry can cause the stator to overheat and fail rapidly.

- Material Compatibility: Selecting the right elastomer for the stator (such as NBR, EPDM, or Viton) is crucial for chemical resistance and temperature stability.

Key Benefits

- Handle High Viscosity: Perfectly suited for thick fluids like sludges, pastes, and heavy oils that would stall other pumps.

- Shear Sensitivity: The gentle movement ensures that delicate fluids (like polymers or food products) aren’t damaged or churned during transport.

- Solid Handling: The flexible elastomer stator allows the pump to pass abrasive particles and solids without clogging.

- Self-Priming: PC pumps have high suction lift capabilities, making them excellent for emptying tanks or pits.

- Precise Metering: Since flow is proportional to speed, they are often used for accurate chemical dosing.

Choosing the Right Pump

Selecting the ideal progressive cavity pump depends on your flow rate, discharge pressure, and the specific characteristics of your fluid.